Zhengzhou Shine abrasives Co.,Ltd, is a special super abrasives tools manufacturer and exporter with

a histroy more than 10 years.

We are located in China Abrasives centre,Zhengzhou city of Henan province.

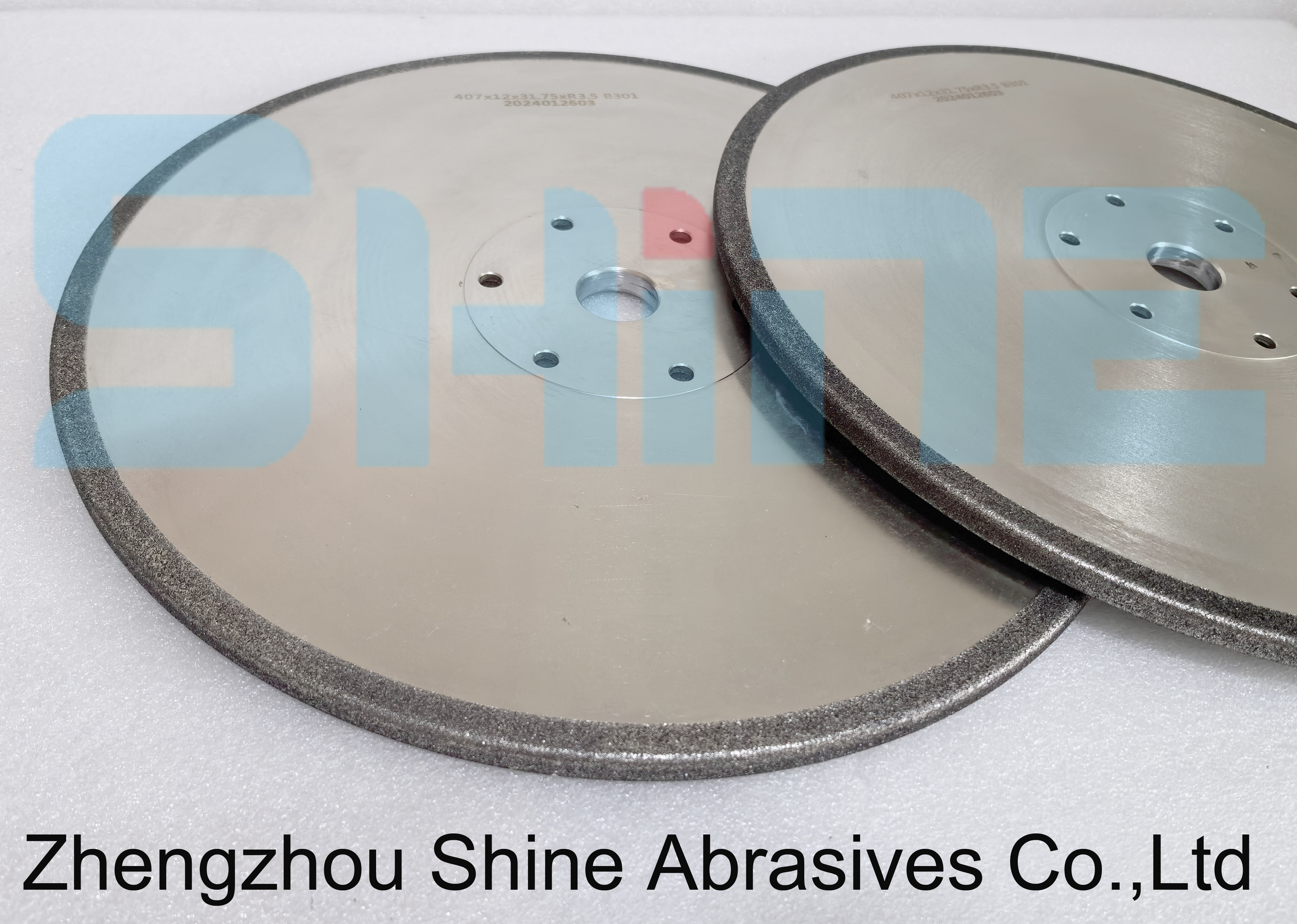

Our Majored products are including:Resin bond diamond and CBN

grinding wheels,metal bond diamond wheels,vitrify bond CBN

wheels,electroplated diamond tools, PCBN cutting tools.CVD dressing

tools.

All our products are made strictly according International standard

and our quality control systems.which leads our products sell well

to our clients all over the world.Shine Abrasives diamond and CBN tools overseas services

territory have covered overseas countries and regions such as

Canada,the United States, and

Poland,Netherlands,Italy,Norway,others countries in Europe,also

convered the areas in South America,Asia and

Africa.

Our goal is to offer customers the finest, most reliable and

durable abrasive tools available at the most reasonable prices and

to offer the best service after the sale available in the industry.

We thank you for your support in the past, present, and future and

wish you success in all your endeavors.