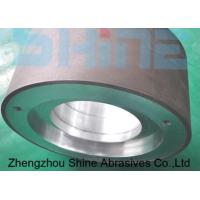

Centerless Grinding Wheels 6A1 405mm Diamond For Tungsten Carbide

Shine Abrasives Resin Bond Diamond Centerless Grinding Wheel 6A1

405mm Diameter.

Mainly used for grinding tungsten carbide, ceramics, magnetic

material, PCD and PCBN compositives.

Main sizes form of Shine Abrasives Centerless Grinding Wheels 6A1 405mm Diamond For Tungsten Carbide

| Abrasive Material:Diamond | Bond Type:Resin |

| Diamond Grit:D107 | Wheel Diameter: 405mm |

| Wheel Bore:203.2mm | Wheel Weight:45kgs/PC |

| Wheel Thickness:205mm | Concentrate: 100% |

Other standard sizes also are available as requested.

Features of Shine Abrasives Centerless Grinding Wheels 6A1 405mm Diamond For Tungsten Carbide

Good self-sharpening

Sharp cutting edges

High efficiency at grinidng

Less heat generating when working

High surface finish after grinding

Centerless Grinding Introduction

Centerless grinding is a kind of grinding process. There are two

grinding wheels, a guide wheel and a grinding wheel. The guide

wheel drives the cylindrical workpiece to rotate on the pad iron,

and the grinding wheel plays a role in grinding the workpiece.

Centerless grinding belongs to the weekly grinding method.

Grinding principle:

The centerless grinding method is composed of three mechanisms:

grinding wheel, adjusting wheel and workpiece support (bracket).

Among them, the grinding wheel actually performs the grinding work.

The adjusting wheel controls the rotation of the workpiece

and makes the workpiece feed speed.

As for the workpiece holder, which supports the workpiece during

grinding, there are several matching methods for these three parts,

except for stopping the grinding, the principle is the same.

The centerless grinding wheel is a grinding wheel installed on the

centerless grinding machine. It interacts with the guide wheel and

the supporting plate to form a grinding method. The workpiece to be

processed is supported by the supporting plate, and the guide wheel

moves to the direction of the supporting plate. circular motionWhen

the workpiece is driven to rotate,

it is ground by a centerless grinding wheel. When grinding the

workpiece, the surface quality is high and the precision is

relatively high.

In grinding, it is also very important to select the particle size

of the grinding wheel.

Coarse-grained centerless grinding wheels are often used for rough

grinding.

For processing, only workpieces with low requirements can be

processed. Generally, in order to speed up the grinding speed

during processing, this method is used for the processing of

workpieces with a large amount of processing. This is because of

its fast processing speed.

but the finish of the workpiece is lower. The quality accuracy of

the workpiece processed by the fine-grained centerless grinding wheel is the opposite. The processing speed is slightly

slower, but the workpiece to be processed has a high smoothness.

Therefore, the choice of centerless grinding wheel is to be

selected according to the technical process requirements of the

workpiece.

It also includes the selection of hardness, tissue density and

particle size of the grinding wheel. Grinding different workpieces,

selected cuts

Fluids are also different. Ordinary iron, we only need to use

ordinary cutting fluid, and kerosene is needed for cold cutting

when grinding aluminum soft parts.

Application picture for reference.