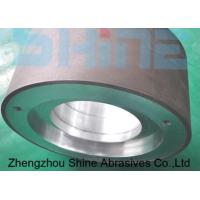

Centerless Grinding Wheels 9A1 300mm Diamond For Bearing Parts

Shine Abrasives Resin Bond Diamond and CBN centerless wheels mainly

are used for tungsten carbide cutting tools,

bearing parts, automobile parts, plungers,cylinders,engine valves.

Our Centerless wheels are divided into Roughing and Finishing.

The finest diamond grit used for centerless Finishing wheel can be

2000mesh, to provide mirror polishing result.

Capacity for the wheel we can make

Max Diameter : 750mm.

Max Thickness: 400mm.

Main sizes form of Shine Abrasives Centerless Grinding Wheels 9A1 300mm Diamond For Bearing Parts

| Abrasive Material:Diamond | Bond Type:Resin |

| Diamond Grit:D126 | Wheel Diameter: 300mm |

| Wheel Bore:127mm | Wheel Weight:35kgs/PC |

| Wheel Thickness:150mm | Concentrate: 100% |

Other standard sizes also are available as requested.

Features of Shine Abrasives Centerless Grinding Wheels 9A1 300mm Diamond For Bearing Parts

Good self-sharpening

Sharp cutting edges

High efficiency at grinidng

Less heat generating when working

High surface finish after grinding

Centerless Grinding Methods Introduction

1. Centerless cylindrical grinding machine with fixed grinding

wheel frame, the grinding wheel frame of this type of centerless

grinding machine is fixed on the bed, and the guide wheel and the

bracket can be relatively adjusted and moved. During through

grinding or plunge grinding, the guide wheel, Brackets and

Workspiece together for feed and compensation movement.

2. Grinding wheel frame mobile centerless cylindrical grinding

machine, the bracket of this form of centerless grinding machine is

fixed on the bed, the grinding wheel frame and the guide wheel

frame can be adjusted relative to the bracket, and can be fed in

special cases. such unintentional

Most of the grinding wheel and guide wheel spindle of the grinding

machine adopt the form of double support structure.

3. Inclined centerless cylindrical grinder, the center line of the

grinding wheel and guide wheel in this form is inclined at an angle

of α to the horizontal plane. The bracket is fixed on the bed, and

the grinding wheel and the main shaft of the guide wheel are

double-supported structures. The guide wheel frame can be adjusted

relative to the bracket Movement, the grinding wheel frame makes a

feed compensation movement.

Application picture for reference.